The experiment on high manganese steel that were poured in the different temperature!

This is a key lesson I’ve learned from my experience working with high manganese steel, and I’m excited to share it with you all…

One of the most valuable lessons I’ve learned from my experience working with high manganese steel (Gx120Mn12) is the significant impact of pouring temperature on the material’s microstructure—and ultimately, its performance.

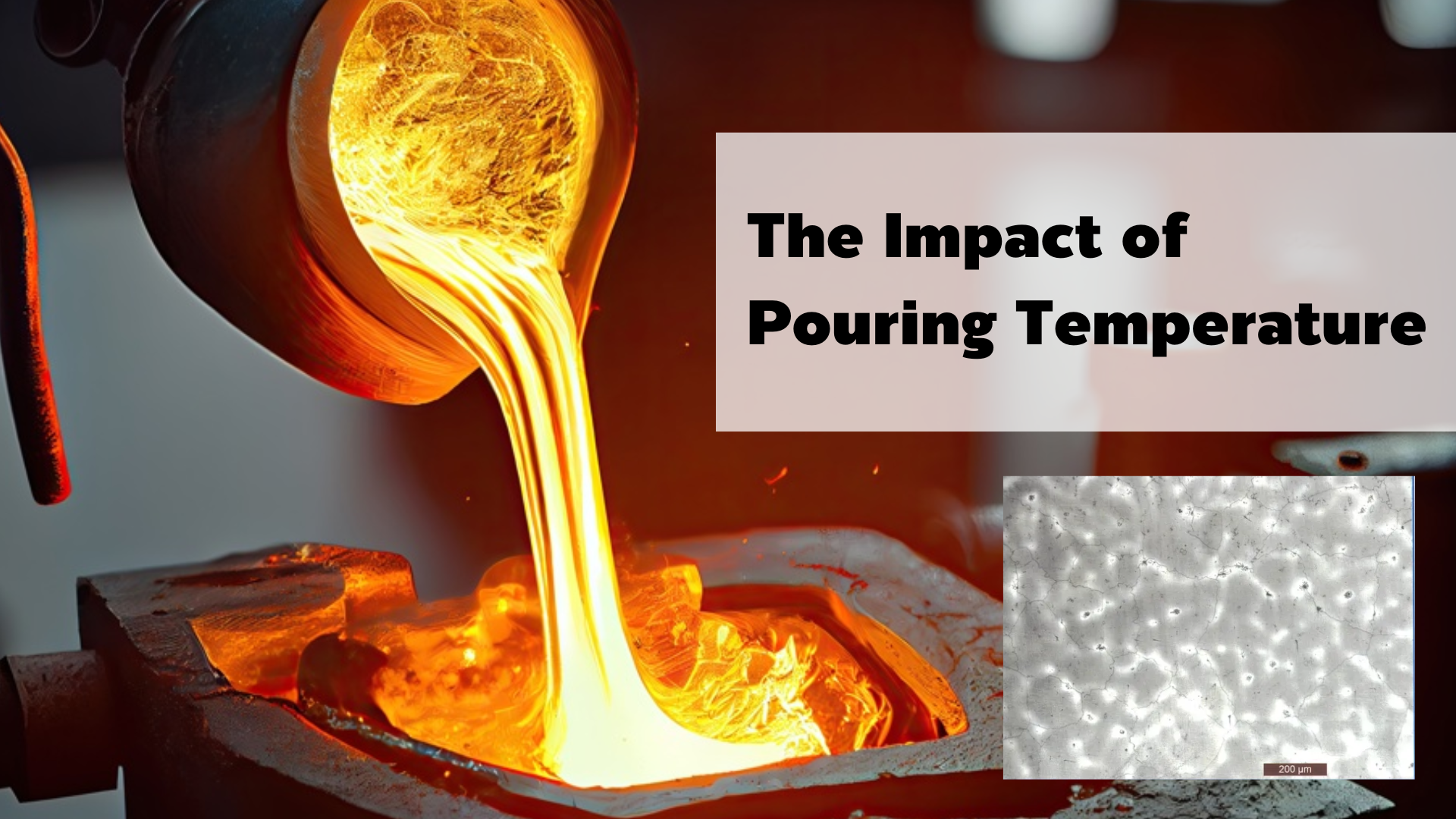

In the attached images, both microstructures belong to samples taken from the same melt. They share identical chemical compositions and underwent the same heat treatment process (solution annealing). In essence, they are “twins”.

However, there is one key difference: the pouring temperature.

– Specimen A was poured at 1430°C, resulting in a grain size that failed at Grain Size No. 1.5 according to ASTM E112.

– Specimen B was poured at 1450°C, with a grain size that failed at Grain Size No. 1.0

This small 20°C difference in pouring temperature profoundly influenced the grain size. Why does this matter? In high manganese steel, grain size significantly affects wear resistance properties. Coarser grain size directly translates to shorter service life, which can make your product appear inferior to competitors’ offerings—potentially costing your business.

This insight underscores the importance of strict control over pouring parameters to ensure consistent quality and maintain a competitive edge.

No responses yet